We have 4 workshops (4,000 square meters) for the product manufacturing, including welding workshop, assembling workshop, electrical cabinet assembling workshop, and machining workshop. We can provide five steel wire hot-dip galvanizing lines and more than 50 hot-dip galvanizing kettle each year.

Office

In our offices, you can find all of our 8 departments, including production department, technology department, electrical department, quality department, finance department, human resources department, sales department, and R&D department.

Production equipment

We have a professional machining team for the production of our hot-dip galvanizing line and related auxiliary machines. Our advanced production equipment includes 6 sets of CNC machining tools, 1 set of wire-electrode cutting machine, 1 set of laser punching machine, and several common machine tools.

Quality test machine

GONGDA has built an advanced quality test lab for the complete test of products, ensuring the reliable quality of our galvanizing machines.

The quality test machines include:

- X-ray diffractometer: Determine the microstructure of the material to optimize our galvanizing technique.

- Electron microscope: Observe the quality and status of the coating to resolve the problems during the galvanizing.

- Salt spray testing machine: Monitor the corrosion process of the product in salt mist.

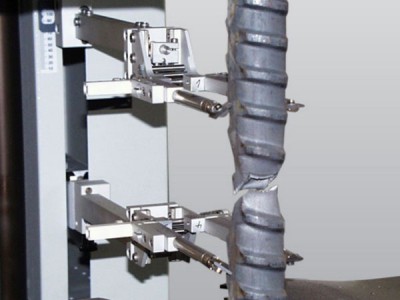

- Tensile testing machine: Test the strength of extension of the steel wire