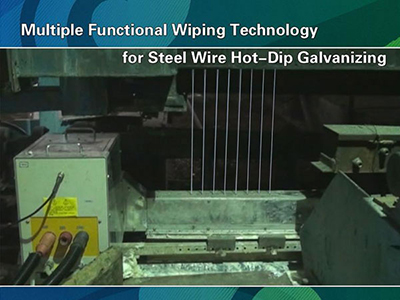

Electromagnetic Field and Gas Wiping Equipment for Steel Wire Hot-Dip Galvanizing Lines

Electromagnetic field and gas wiping equipment for steel wire hot-dip galvanizing lines can wiping the zinc plating layer on the steel wire without touching it. As a kind of efficient wiping machine for galvanization, it can control the surface smoothness and zinc layer thickness precisely just by adjusting the electric field intensity, magnet field intensity, gas flow, and temperature.

Parameter

- Wire diameter: 0.8~8.0mm

- Max. DV value: 120 mm•m/min

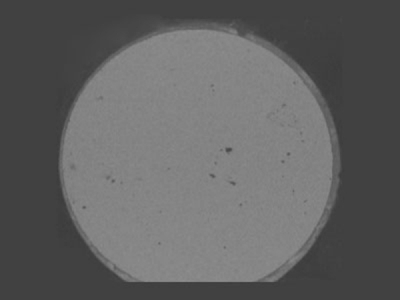

- Zinc layer thickness: 150~400 g/㎡

- Wire number: 6~16 wires

Feature of the electromagnetic field and gas wiping equipment

- The electric field and magnetic field are controlled by a micro computer, so the precision is great.

- The equipment can detect and diagnose the faults of the galvanizing equipment, and the fault alarming and self-protective function are also available.

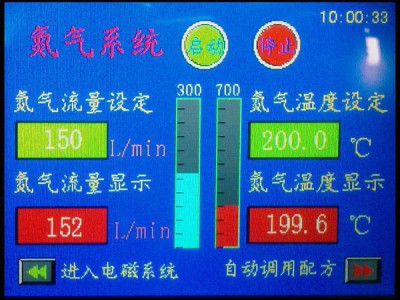

- You can read the gas temperature and flow rate on a digital display. The digital control system is user-friendly and highly precise.

- Our electromagnetic field and gas wiping equipment for steel wire hot-dip galvanizing lines is eco-friendly and has extremely low working noise.

- The coating layer is quite consistent—the precision could reach ±7.5 g/m2. The best wiping performance is 300 g/m2. Thus you can save 20% zinc consumption.

- The whole set of equipment consists of electromagnetic field generator, electric control system, nitrogen heating and flow control system, wiping mechanism, water cooling system, and nitrogen gas system.

Related Products

Inquiry

Other Products