Nitrogen Gas Wiping Equipment for Steel Wire Hot-Dip Galvanizing Lines

The nitrogen pressure wiping system is a non-contact solution designed to precisely control the zinc coating thickness on hot-dip galvanized steel wire, suitable for high-speed galvanizing lines. The air knives deliver a strong wiping force to remove excess molten zinc from the wire surface. With a fixed nozzle gap, adjusting the nitrogen pressure allows operators to fine-tune the wiping intensity and regulate the coating thickness.

The nitrogen wiping system includes precision-machined 316 stainless steel air knives, a robust support frame also made of 316 stainless steel, nitrogen pressure actuators (Japan SMC), an inline coating thickness sensor (from a domestic brand), and a PLC control system (Siemens).

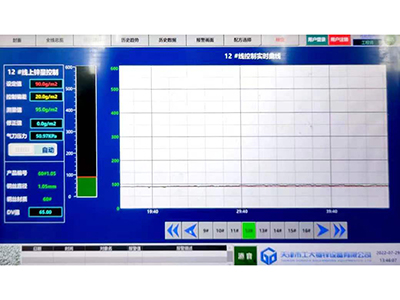

Through the HMI interface, operators can enter parameters such as wire diameter, target coating thickness, and line speed. The inline monitoring system continuously measures the galvanized layer thickness via the sensor coil and compares the data to the set value. A closed-loop control mechanism automatically adjusts the nitrogen pressure actuator to maintain consistent coating thickness. To build an accurate control database, product samples of common wire specifications must be collected and tested in advance. These samples are processed under different nitrogen pressures, line speeds, and nozzle diameters. The measured coating thickness data are statistically analyzed and stored in the PLC system database to support reliable production control.

To achieve high precision and low nitrogen consumption, the system offers six nozzle configurations: ⌀0.8–1.45 mm, ⌀1.5–2.45 mm, ⌀2.5–3.95 mm, ⌀4.0–5.95 mm, ⌀6.0–7.75 mm, and ⌀7.8–9.0 mm. The nitrogen wiping equipment meets the demands of high-speed galvanizing operations, with a maximum DV value up to 220 mm·m/min. It is important to maintain precise tension control throughout operation, requiring both the pay-off and take-up units to consistently keep stable tension. Additionally, spliced joints are not permitted; all wire connections must be welded with a butt-welding machine to ensure uninterrupted processing.

Parameters

- Steel wire material: low, medium, or high carbon steel wire

- Galvanizing types: hot-dip galvanized / hot-dip zinc-aluminum / hot-dip zinc-aluminum-magnesium

- Galvanizing thickness: 80–450 g/m²

- Control precision: ±15 g/m²

- Air knife material: precision-machined 316 stainless steel

- Control mode: PLC automatic control / manual control